This article outlines several PIM and DAM best practices that will enable the creation of “killer” catalogs in an efficient, cost-effective manner.

Separate Content Stewardship from Creative Ownership

Many organizations do not differentiate creative ownership of content from the important roles and tasks associated with ensuring the accuracy, completeness and consistency of product information in context to its intended channel(s) of distribution. This leads to higher catalog production costs due to process inefficiencies and avoidable rework.

Data stewardship insures that data is in compliance with data governance standards, policies, and processes. Creative ownership is responsible for the creation and delivery of the print asset. Since the print asset creation process outlined in this paper is data-driven, there is an interdependency between the creative and data organizations with clear lines of demarcation in terms of responsibility.

It is recommended that organizations formally name data stewards that shepherd product data throughout the lifecycle of the product. Many choose to augment the base capability of the product information (PIM) system with data quality (DQ) tools that help to ensure the accuracy, completeness and consistency of product information. DQ rules can help the steward normalize attributes and their values across similar products from different vendors. This makes tables of similar products look comparable in print and enables effective faceted searches in web shops.

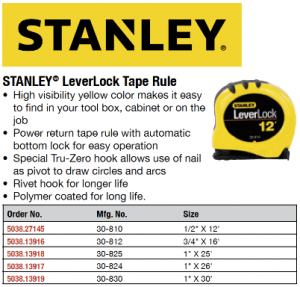

For print, it is important to use DQ rules to remove any invalid characters whenever loading in data from external sources. They can also be used to standardize and enforce units, unit symbols, and their use in table headings and attribute values (e.g. Size (in.) – 3/8″).

The creative staff take the data and transform it to a form for presentation to the customer. What is stored in PIM as product names, long descriptions, features & specifications, and attributes get turned into catalog or flyer entries that are visually appealing.

The data steward is the person responsible for the creation and maintenance of product information content. The creative person owns how that information is presented to the customer. Keeping the responsibilities of the roles separate makes the responsibility to resolve issues clear.

Attribute Your Product Data for Print

Not every product or item may be destined for placement in a print asset. Identify each product and item that are to be shown in catalogs entries and tables and mark them as such in PIM. Also, mark which attributes are to be shown. A simple check box or purpose fields may be used in the PIM.

A separate catalog or flyer classification system may be used to organize products and items. This provides the graphics designer a virtual organized checklist of which products and items are to be included in particular catalog or flyer.

Aside from which products and items are to be in a particular print asset, they need to be in the correct order in which they are to appear. Fields to place items in the proper row order in tables and attributes in the proper column order should be used. Items need to be specifically sequenced by attribute values as alphabetical sorting does not work well for items with dimensional attributes like hardware (e.g. bolt sizes 3/8″ is smaller than 1/2″).

Implement a process that checks to make sure that the correct product and item images are assigned in PIM. This will eliminate the graphics designer from having to go on a time wasting “image safari” hunting down which images to use.

Plan your publishing schedule to include both product content and pricing. Most PIM systems allow a myriad of ways to price products. In order to create flyers in advance of a future advertising event, pricing for the event in PIM needs to be in the system by the time designers start working on the flyer. The PIM also needs to have a price “key” for the sale event that will enable the correct pricing to be placed on the page.

By using PIM to organize, identify, and sequence products, items, and their attributes; the creation of the print document in the desktop publishing system becomes seamless and removes error prone and tedious tasks from the creative process.

Ensure Images Are “Print Ready”

Using a DAM establishes a single source of truth for product images, drawings, and other visually-oriented documentations. One of the things to be aware of is the difference between how colors are created and perceived on computer monitors versus how they are produced by the printing process.

Pixels on computer monitors are triads of red, green, and blue (RGB) dots. One can vary the intensity of each RGB sub-pixel to go from black (r=0, g=0, b=0) to white (r=255, g=255, b=255). The colors values are added in the brain to perceive the proper color. Images formats like jpeg and gif use RGB in to represent color and are used by most websites. These images are tuned to look good on monitors that have 72 or 96 pixels per inch.

Printing presses are different from interactive display devices, combining inks to create images. Most use cyan, magenta, yellow, and key (black), otherwise known as CMYK, which is laid down on paper using a subtractive process. The math behind the CMYK and RGB color spaces is different, allowing for different ranges of color to be perceived in each model.

For the print process, it’s recommend that product images be in the CMYK color space with sufficient resolution for printing. Knowing the target size of the image on paper will help to make sure there are sufficient pixels. Printing a 2” square low resolution image as a 4” square on a high quality press will result in images that look fuzzy or have “jaggies”.

Using a DAM to ingest high resolution camera images to automatically create low resolution derivatives for the web is the best solution. That way one has both high quality product images suitable for printing and images for quick delivery for the web. Using 300 dpi images in the CMYK color space in TIFF format for print is a good place to start. Whenever possible, use vector artwork for logos. That way, they’ll scale to any size in the desktop publisher and look great when printed.

Prepare for Change

Since this is a data-driven approach, it’s common that when things don’t “look right” on a page it is due to errors in the incoming data. A process needs to be put in place whereby the creative staff can have data issues quickly resolved. The emphasis on quickly resolving data issues is intentional. Catalog creation productivity drops significantly when designers are blocked waiting for data issues to be resolved.

A recommended solution is to appoint a data steward to act as a single point of contact to investigate and resolve any data discrepancies uncovered in the creative process.

Connect PIM and DAM to Print

On one hand we have PIM and DAM that contains all of the product information needed to produce and advertisement or catalog entry. One the other is the desktop publishing system used to create print assets. A means to connect the two worlds together is required.

That bridge between the data and creative person is the publishing hub. The publishing hub acts as a middleman to connect the desktop publishing tool to the data in the PIM and images in the DAM.

The publishing hub delivers content to the page and is the third and essential component to that ties the analytical data world to the creative universe. Implemented correctly, it enables teams to be far more efficient and able to meet the ever growing demand for more creative presentation of product information.

Conclusion

This strategy of coupling product information management (PIM) and digital asset management (DAM) systems to the desktop publishing tool with a publishing hub has been proven to accelerate, improve the quality of, and minimize the cost of creating customer facing catalogs, flyers, and brochures. Following the process and technology changes outlined above will help companies to realize the full potential of the investment required. Why bother? Killer catalogs produce sales.

About the Author

Dave Nacy, Managing Consultant at Infoverity, LLC. Dave holds a BS and MS in Systems Engineering from Oakland University and leads Infoverity’s Digital Publishing Solutions. He helps companies connect their creative staff to product data systems in order to efficiently publish sales and marketing content in the form of electronic and printed catalogs, brochures, and flyers. Previously to joining Infoverity and earning the reputation as the “priint master”, Dave’s work experience includes being the print lead at Heiler Software and Innovative Systems and Services.

About Infoverity

Founded in 2011, Infoverity is a leading global professional services organization focused on solving business problems caused by the proliferation and diversification of data in large enterprises. IDG’s Computerworld recently named Infoverity to the 2016 List of Best Places to Work in IT. Infoverity provides Master Data Management (MDM), Product Information Management (PIM) strategy and implementation solutions that help clients in the retail, consumer goods, manufacturing and healthcare sectors to simplify and maximize the value of their information. Partners include Informatica, IBM, Priint (WERK-II), Reltio, Riversand, SAP and Trillium Software. Infoverity’s global headquarters is in Dublin, OH, and additional service and support offices are located in Spain, Germany and Russia. For more information, please visit https://www.infoverity.com and follow Infoverity on LinkedIn , Facebook or Twitter.